The device does not work. Is the battery operational, the switch turned ON and the hand-held transmitter successfully connected?

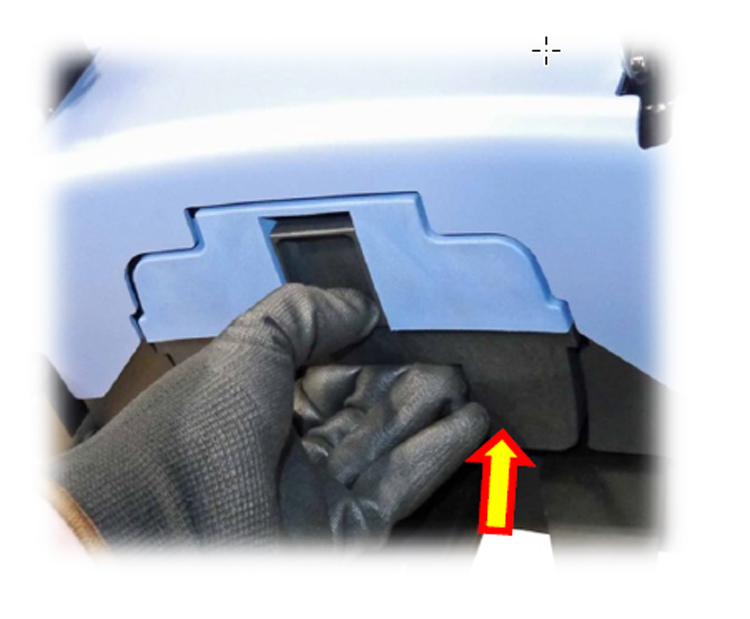

Is the battery snapped correctly in the device?

There is a recess for the battery on the bottom side of the basic device.

The battery must click audibly.

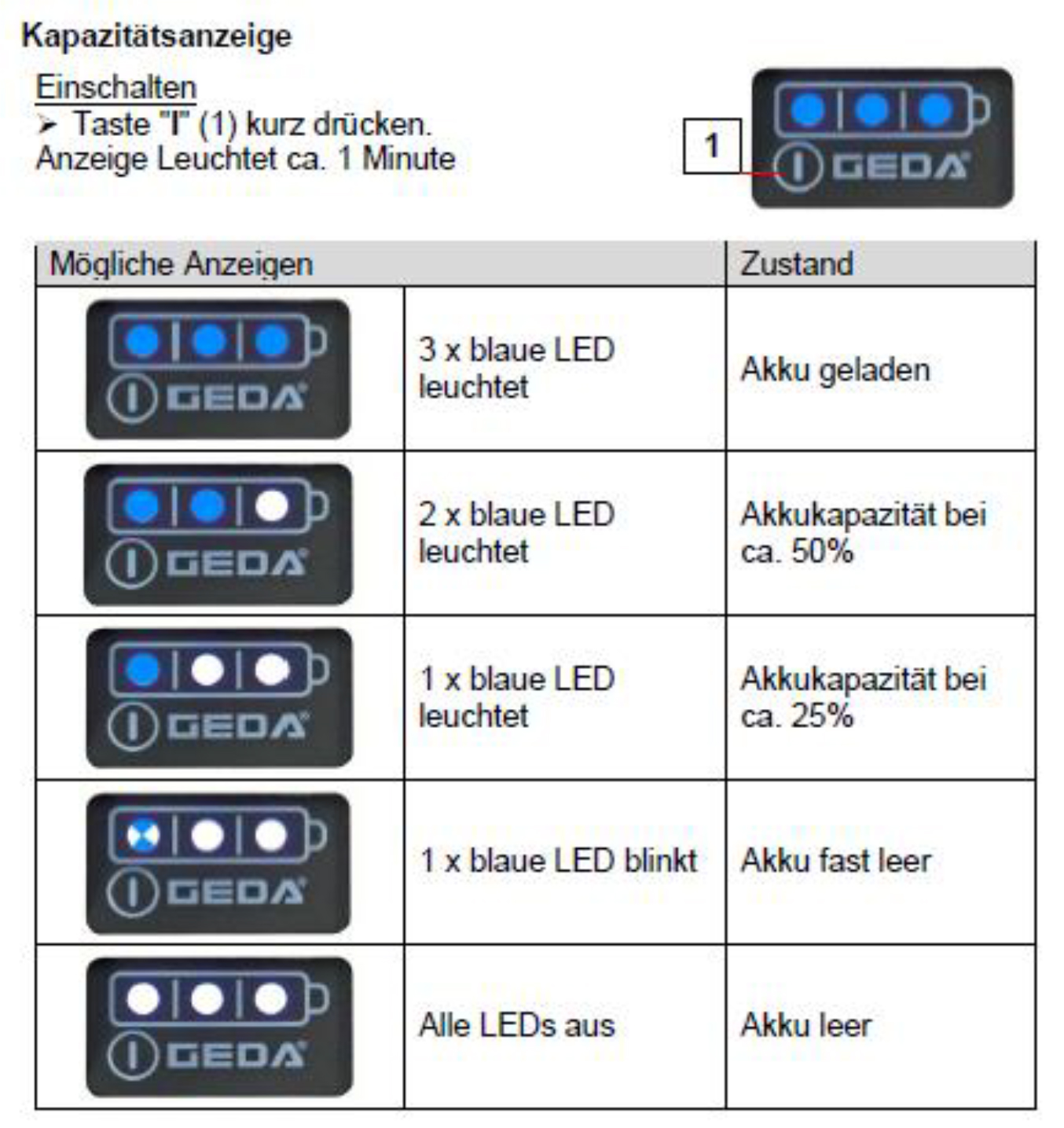

Is the battery sufficiently charged?

Press the switch on the battery to check the charge level.

The number of LEDs shows the battery status.

Analyze the battery status according to the graphic and change the battery if necessary.

Is the base device switched on?

Press the ON / OFF switch on the side of the base device.

The blue light ring on the switch lights up cyclically as confirmation.

As long as the base device is not activated by the hand-held transmitter or smartphone, the blue ring flashes (cycle approx. 1 second) until the hand-held transmitter or smartphone is activated.

Has the hand-held transmitter or smartphone application been successfully connected to the basic device?

Connect hand-held transmitter with basic device.

See details for connection in the video.

Does your hand-held transmitter still not connect?

The locking lever may not be fully closed.

As soon as the locking lever has been opened again, the device must be switched on again and the hand-held transmitter reconnected.

No hand transmitter available? If the WLAN option is built into the device, activate to control by the smartphone app.

Check whether your BatteryLadderLIFT is capable for Wifi.

Pay attention to the symbol in the picture to see whether control via WLAN is possible.

If the symbol is present, install the control app according to the video sequence.

Then operate the BatteryLadderLIFT with the smartphone control.

Do you have questions about the assembly? Here you will find tips and tricks on the belt, locking lever and roller guide.

Assembly video for BatteryLadderLIFT.

The video shows step by step the structure including the assembly of the ladder section.

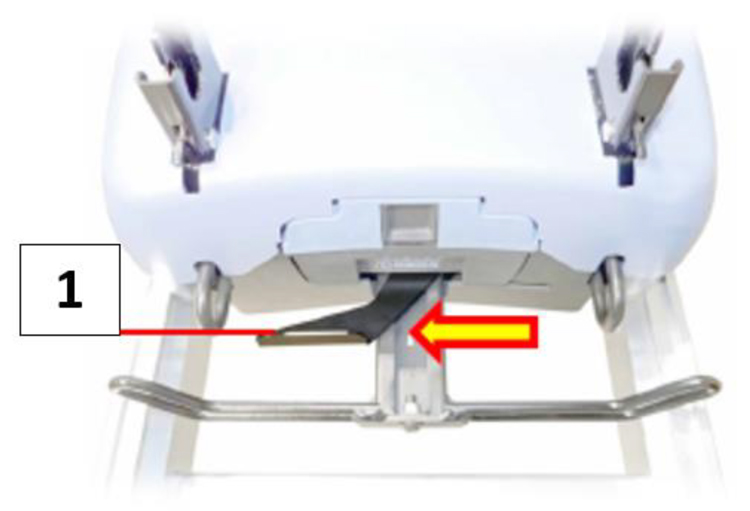

Is the belt in correct orientation fixed to ladder section header?

Make sure that the belt is not twisted.

Fasten the hook as shown in the picture.

Has the basic device been correctly retracted into the ladder guide and is the locking lever locked?

The drive unit may not be correctly attached. Track rollers or guide rollers may not be correctly inserted in the ladder section.

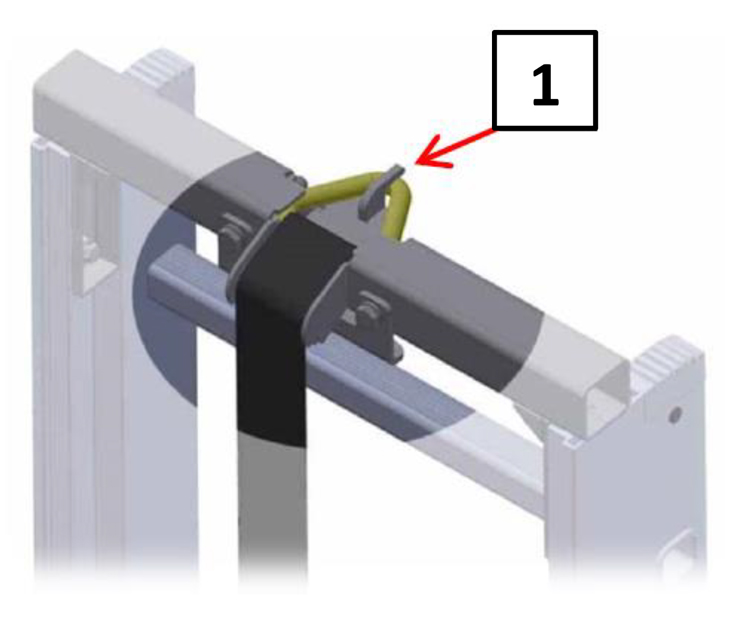

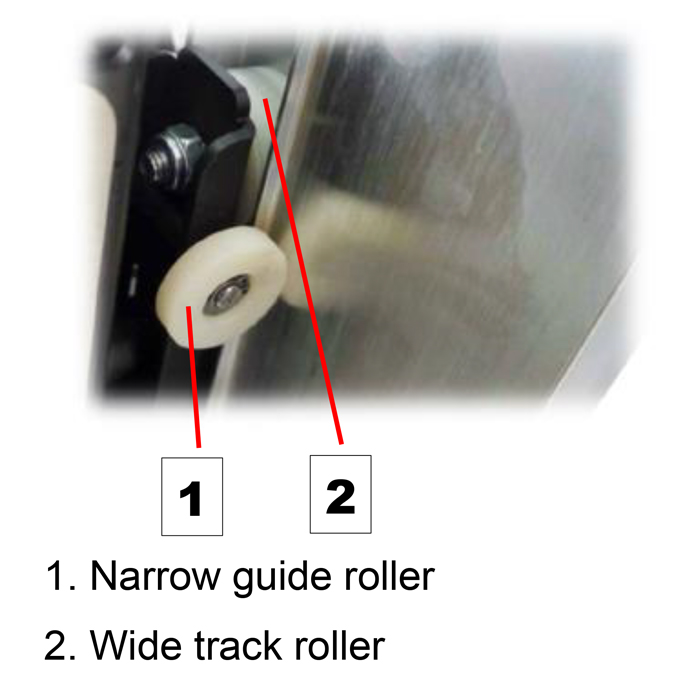

Check the narrow guide roller for correct seating.

See the picture for correct postion of roller (position 1).

Check that the wide track roller is in the correct position.

The seating of the role (position 2) is shown in the picture.

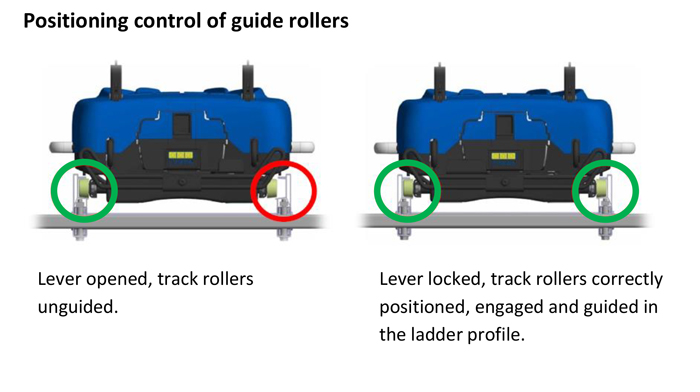

Check whether the rollers are correctly engaged in the guide rail when the locking lever gets closed.

While the locking lever is closed, the rollers move laterally into the ladder guide. Check correct position according to picture.

Does the lift move in the opposite direction to the travel command?

If the travel command and travel direction does not match, the belt is wound in the wrong direction on the shaft.

Watch our video to learn how to wind the belt in the correct direction.

Is the journey partially interrupted despite the travel command?

Stop can be caused by slack belt or overload.

Always keep the belt taut during extension to prevent the switch-off.

Does the device stop while moving under load?

If there is too much load on the platform, the overload-stop is activated. Reduce the load on the platform. The overload is deactivated after a short waiting period. If the load is now less than the value of the overload, the platform can be moved again.